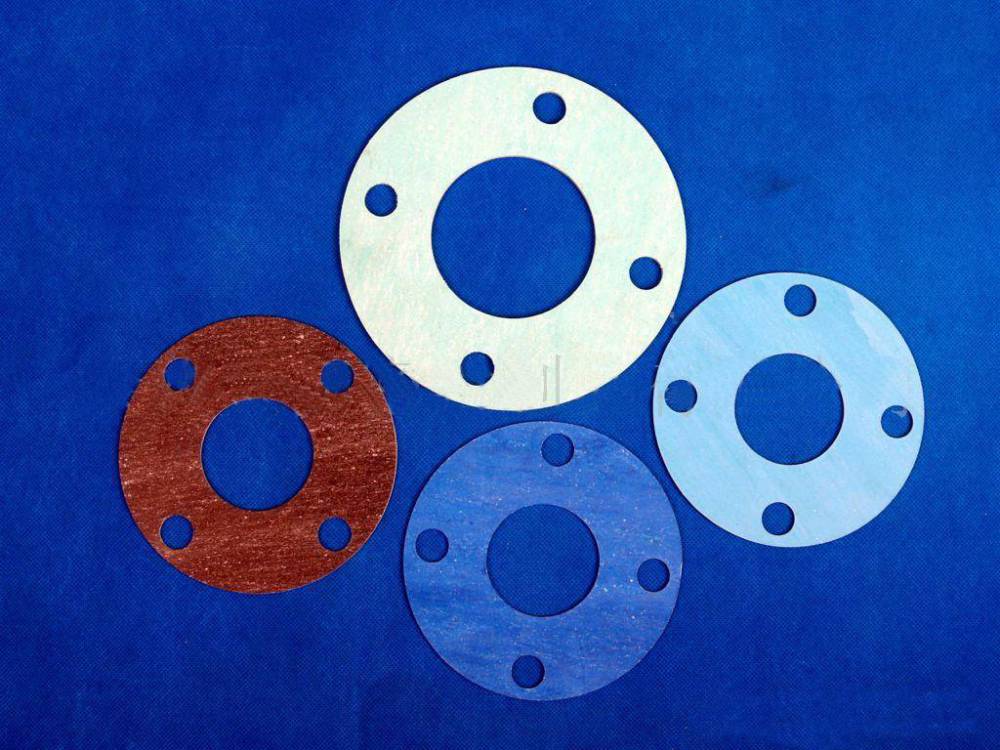

Gasket sealing indutry - Godworker oscillating knife cutting machine

Technical Parameters

|

Model |

GW-1625N / 1630N oscillating knife cutting machine |

|

|

Working area |

2500*1600mm |

3000×1600mm |

|

Rated power |

12KW |

|

|

Fixed mode |

Flat plate table |

|

|

Multi-function head |

Oscillating knife head / Penumatic head / Servo knife for option |

|

|

Tool configuration |

Multiple cutting knives |

|

|

Safety device |

Using infrared sensors, responsive, safe and reliable. |

|

|

translational velocity |

800-1200mm/s |

|

|

Cutting speed |

200-800mm/s(according to different cutting materials) |

|

|

Cutting thickness |

≤100mm(according to different cutting materials) |

|

|

Cutting materials |

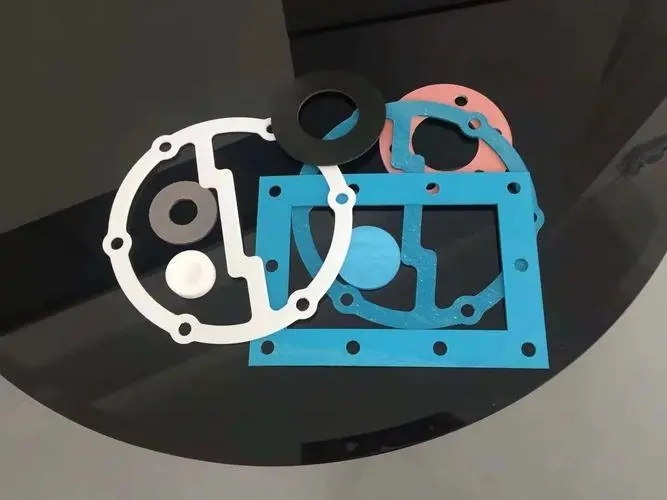

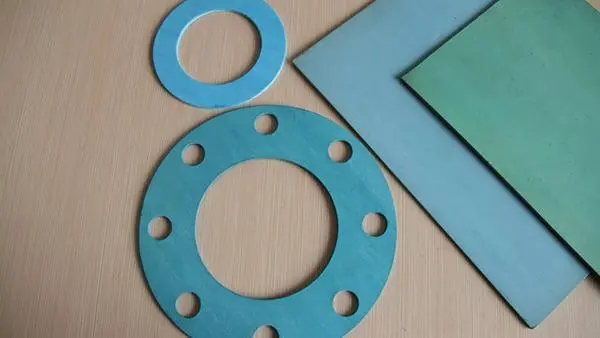

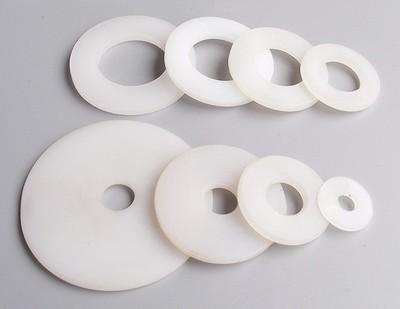

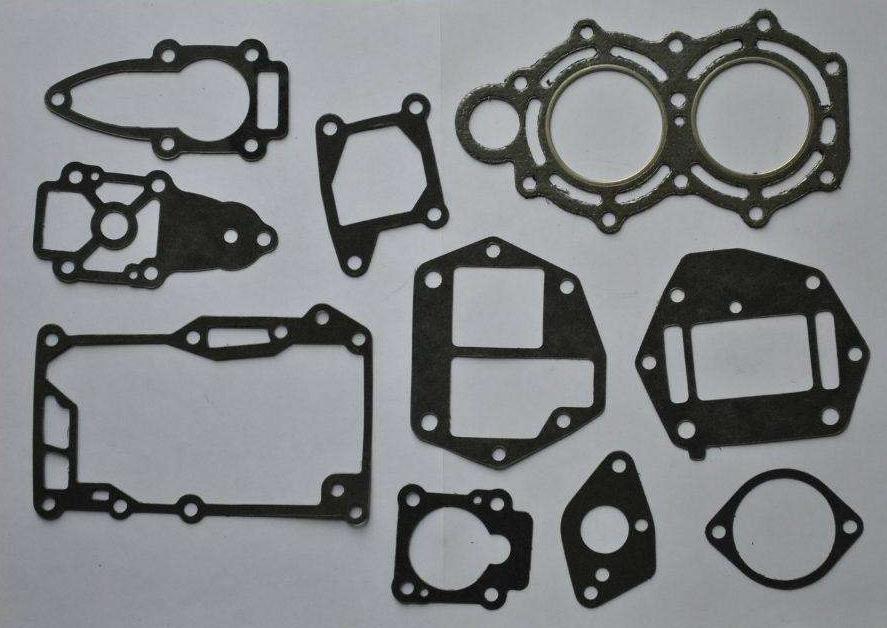

Leather, all kinds of clothing flexible material, Sponge composite leather, PVC, soft glass, Silicon, rubber |

|

|

Repeated accuracy |

≤0.1mm |

|

|

Machenical Precision |

Max. 0.02mm |

|

|

Driving system |

Delta servo motors + drivers / Panasonice servo motors + drivers (option) |

|

|

Transmission system |

Helical gear rack + HIWIN linear rail (X,Y axis 20mm) |

|

|

Control system |

Double 32bit RISC CPU + Huge reparogrammable logic gate arrays FPGA |

|

|

Operation mode |

Operating flat form+Data output control software |

|

|

Support format |

AI, PLT, DXF, CRD, etc |

|

|

Control Panel |

Ruida LCD touch screen / Kinco (option) |

|

|

Capacity |

4GB |

|

|

Instruction system |

HP-GL compatible format |

|

|

Voltage |

380V +220V, 50/60Hz; |

|

|

Vacuum pump |

7.5KW vacuum pump |

9.0KW vacuum pump |

|

Packing size |

3550*2150*1600mm |

4300*2150*1600mm |

|

Gross Weight |

1300KG |

1500KG |